Air line filter-lubricators are a necessity for long life of your tools and hoists. Oil injected in the tool and reconnecting to the air line lasts from 3 to 10 minutes of the tool running : the higher the tool speed the faster the blades heat, evaporate the oil, and run dry. Most blades travel a distance equal to 1.2 miles in one minute (over 100 feet per second) and centrifugal force gives

even a small blade a weight equal to 5 or 6 pounds. The heat that is generated without oil will cause blades to chip and the chips get in bearings and cause failure.

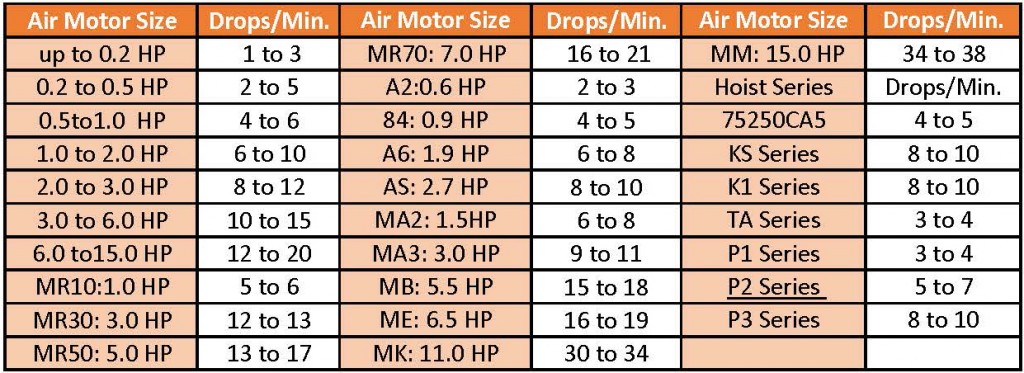

How much oil is needed per minute of running? See chart below for the average use.

When using GD Hoists, use 540397 or 533485 air line oil. Increase the drops per minute shown in the above chart x 32. Only a small portion of the drops in the sight tube actually go into the air stream, the rest of the drops go back into the oil storage bowl. The best way to test if you are getting sufficient oil is to hold a piece of hard finish white paper at the exhaust for one (1) minute. If you do not see oil on the paper you are not getting sufficient oil to the unit.

When you have self feed drills or Air feed drills running free much of the time during their stroke, at 80 psi air pressure or higher, use GD Hoist oil (536333 for one gallon). The film strength of this oil is such that oil drop lubricators must be used, as the oil will not always break up for mist types.

Should you want commercial equivalents of these lubricants, contact the Technical Service Supervisor. Our oils have been selected after much testing. Other oils may not be adequate and may gum up your units causing the loss of

factory warranty.

For best results, use 50 micron or better filters. Always mount lubricators as close to the tool as possible. Always mount lubricator higher than the tool or at least the same height. If you use a mist type and it is close to a tool with long run cycles (10 seconds or more) you may get sufficient lubrication with the lubricator lower than the tool. Use a lubricator for each tool as feeding more than one tool usually results in one tool getting oil and the rest running dry and soon failing due to the lack of lubrication.

The lubricators that inject oil right at the inlet of the tool, when each cycle is initiated, are excellent for short cycle applications like screw driving, nut setting, or short hoist lifts. On many fastener applications the tool run is so short that regular lubricators do not get oil to the tool. This type of lubricator makes sure oil is at the tool through the small feed tube inside the air hose. In the case of most hoists, it is often not easy to get a lubricator close to the hoist or on the same level or higher than the hoist. These “one shot” type lubricators will solve the problem.

Standard air line filters do not remove all of the water in an air line. If you see water in your filter at the individual tool you should consider a dryer at your compressor to protect your tool from rust and early failure. Dryers can be refrigeration, coalescing, or desiccant type.

GD Hoist’s products are classified as non-hazardous manufactured items, defined in the OSHA 1910.1200 Hazard Communication Standard as “Articles”. These products, under conditions of normal use, do not release or cause exposure to a hazardous chemical.

Under normal conditions of use, lubrication products sold separately for or used within these tools should not cause an exposure hazard. Refer to the Material Safety Data Sheet for Safety and Disposal Information. M.S.D.S. sheets are available upon request from GD Hoist.

GD Hoist is also aware of, and complies with, the provisions of section 611 amendments to the Clean Air Act of 1990. No ozone depleting chemicals have been used in the manufacture of our products.

If you resell or distribute these products, you have the responsibility for ensuring that the Material Safety Data Sheets are provided to the purchaser.

Proper lubrication is essential to the economical operation of pneumatic tools. GD Hoist tools perform better and their life is extended by using the recommended lubricants. The following lubricants have undergone extensive testing and are recommended for use with GD Hoists products.

.